Working on a line means a vehicle remains idle, sometimes for hours, burning fuel the entire time.

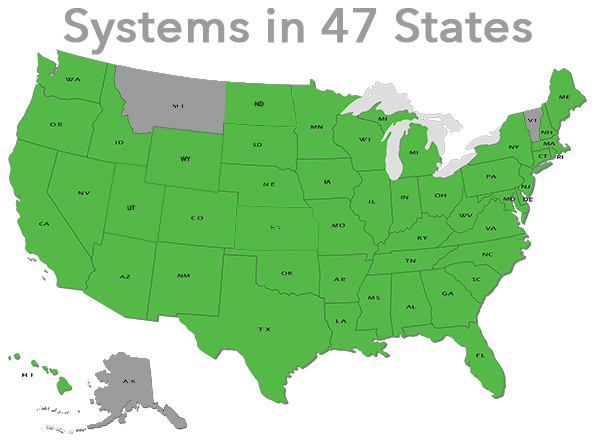

The ZeroRPM® Idle Mitigation System® eliminates the need to use the engine at idle, reducing operating costs considerably. Furthermore, the electric powered takeoff unit functions like the factory-standard hydraulic pump, allowing the boom to be used without running the engine.